The purchase of 24V power supply should be cautious(3)

rectangular wave of 20 kHz.

Due to the poor working conditions of the welding machine power supply and frequent short-circuit, arcing and open-circuit changes, the working reliability of the high-frequency inverter rectifier welding machine power supply has become the most critical issue and the most concerned issue by users. . The microprocessor is used as the relevant controller of pulse width modulation (PWM), and through the extraction and analysis of multi-parameter and multi-information, the purpose of predicting various working states of the system is achieved, and then the system is adjusted and processed in advance to solve the problem. The reliability of high-power IGBT inverter power supply is improved.

Foreign inverter welding machines can achieve a rated welding current of 300A, a load duration rate of 60%, a full-load voltage of 60~75V, a current adjustment range of 5~300A, and a weight of 29kg.

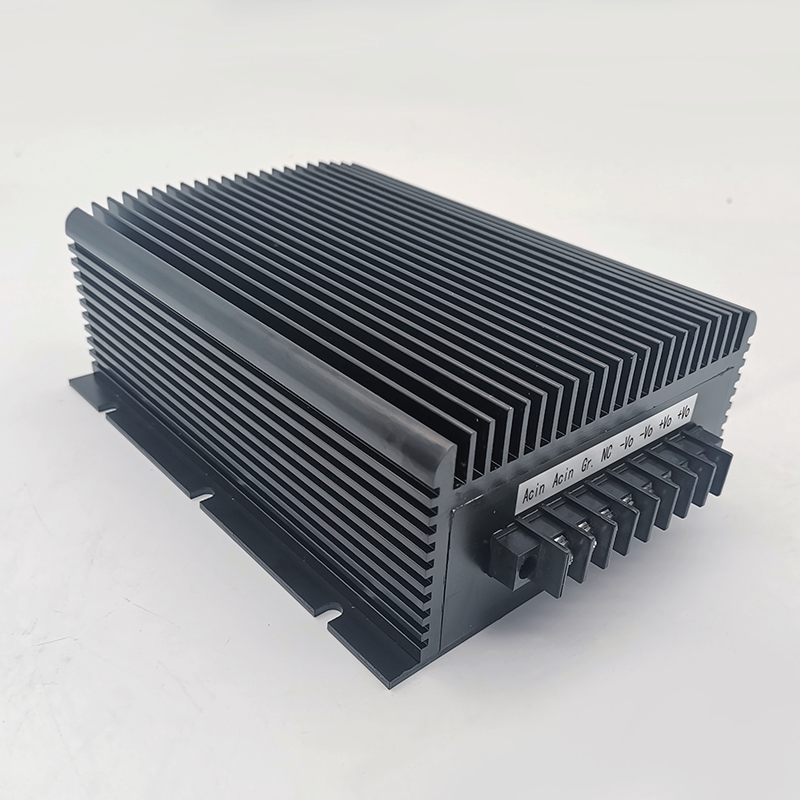

The advent of the era of intelligence has led to more and more electrical equipment. In order to protect the reputation of the company and ensure the safety of consumers, the insulation problem must be considered when purchasing power modules. If the insulation of the power module is insufficient, it will be used for a long time. There may be leakage of electricity. Once a consumer is injured, it will have a serious impact on the brand image of the company, and it may even make a company slump and disappear from the market completely.

24V power supply can be bought in many places, and they are not scarce items, but it is necessary to pay attention to the flame retardant performance and insulation performance during the purchase process, so as to buy high-quality power modules and protect their own interests.