What does a DCDC converter look like?(4)

Electrolytic capacitors, as well as monolithic electrolytic capacitors, which use sulfuric acid as the insulating medium, which allows for greater capacity savings, are made into smaller volumes, and are marked with a + symbol, some with an a symbol. Typically used for low frequency crosslinking and bypass filtering. The disadvantage is that the loss of mesons is greater. Monolithic electrolytic capacitors are due to their special properties. The performance of the material is better than that of ordinary electrolytic capacitors, and the frequency characteristics are better, but the capacity cannot be too large, and can be used in precision circuits and timing circuits.

(6) For the module power supply, some manufacturers have a fixed resistance directly connected to the adjustable terminal (ADJ) from the factory. When using, the user must configure a potentiometer with the corresponding resistance value to replace the fixed resistance. However, it should be noted that when the adjustable terminals are in an open state, loading is never allowed.

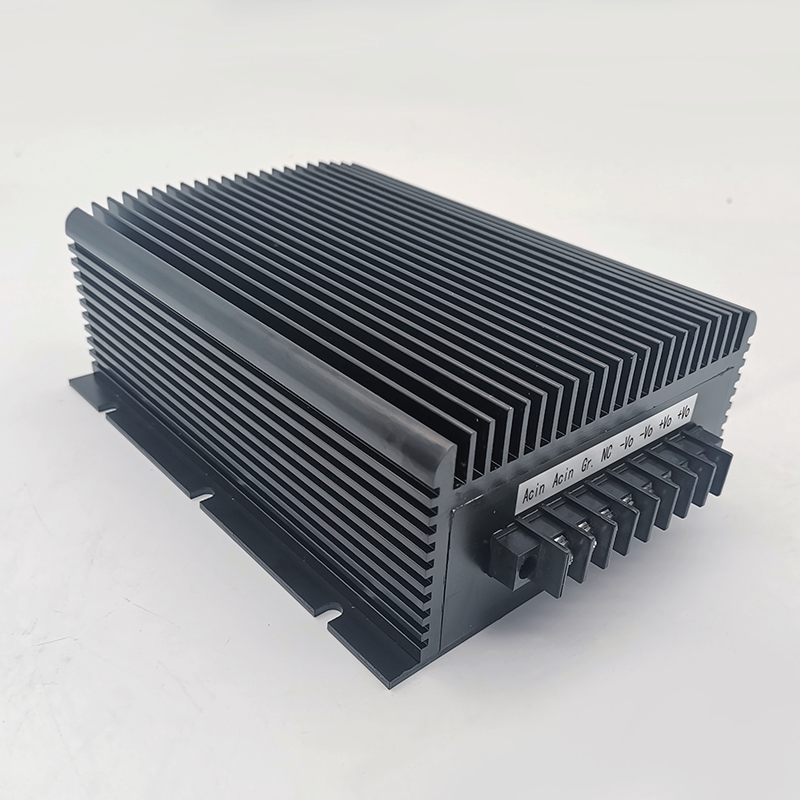

(7) In order to achieve sufficient heat dissipation, the module power supply should be installed in a location with better air convection. Generally, when the working current of the linear power supply is above 4A, or the working current of the switching power supply is above 7A, forced air cooling should be installed. In addition, no other items are allowed on the module power supply housing.

(8) The module power supply is generally suitable for resistive-based loads. If it needs to be applied to capacitive-based or inductive-based loads, it should be explained in the order contract in advance and customized by the manufacturer.

DCDC converter Ceramic capacitors include ceramic dielectric capacitors, ceramic chip capacitors, ceramic tube capacitors and ceramic semi-variable capacitors. It is mainly non-polar, the dielectric material is better, and the capacity cannot be too large, suitable for high frequency circuits.

Five: Batch inspection and high temperature aging test

Regardless of how much control the product material and production process are, aging needs to be checked. Because the incoming inspection of electronic components and transformers is difficult to control, the quality stability of this batch of power supplies and whether the materials are detected to have potential safety hazards can only be detected through aging and high-temperature sampling of the entire batch of power supplies.